Difference between revisions of "1D Manholes"

Tuflowduncan (talk | contribs) |

Tuflowduncan (talk | contribs) |

||

| Line 84: | Line 84: | ||

<br> | <br> | ||

With other parameters defined in the section above. | With other parameters defined in the section above. | ||

| − | The calculated flow area in the manhole is 3.6m<sup>2</sup> and 1m<sup>2</sup> in the adjacent culvert whilst the flow is 2m<sup>3</sup>/s for both Q<sub>p</sub> and Q<sub>om</sub>. Therefore, V<sub>m</sub> equals: | + | The calculated flow area in the manhole is 3.6m<sup>2</sup> and 1m<sup>2</sup> in the adjacent culvert whilst the flow is 2m<sup>3</sup>/s for both Q<sub>p</sub> and Q<sub>om</sub>. |

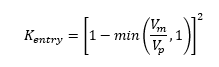

| − | + | Therefore, V<sub>m</sub> equals: | |

[[File:Vm1.PNG]] | [[File:Vm1.PNG]] | ||

<br> | <br> | ||

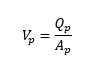

And V<sub>p</sub>: | And V<sub>p</sub>: | ||

| − | |||

[[File:VP1.PNG]] | [[File:VP1.PNG]] | ||

<br> | <br> | ||

Using these in the K<sub>entry</sub> equation provides a loss coefficient of: | Using these in the K<sub>entry</sub> equation provides a loss coefficient of: | ||

| − | |||

[[File:K entry1.PNG]] | [[File:K entry1.PNG]] | ||

<br> | <br> | ||

Revision as of 20:24, 25 May 2021

Page Under Construction

Introduction

Manholes are typically chambers used to provide one or all of the following; maintenance access, change in culvert direction, connections and change in culvert dimensions. By default, manholes are automatically created within TUFLOW at all culvert nodes, any manually created manhole will override the automatically created manhole.

Manholes are used at culvert junctions to dissipate energy due to:

- Expansion/contraction of flow within the manhole chamber and outlet culverts.

- Change in direction of the culverts (i.e. a bend/deflection).

- Change in height, width or diameter and/or invert level of the adjoining culverts.

The presence of a manhole at a junction point will override the exit loss of any culvert discharging into the manhole and entrance loss of any culvert taking from our of the manhole.

There are 3 types of manholes:

- "C" for circular chambers.

- "R" for rectangular chambers.

- "J" for junctions without a chamber

Losses

When modelling conduit pipe flows, the head losses that the flow in pipe are subject to are made up of major losses (or friction losses) and minor losses (or local losses). Major losses are caused by forces between the flow and wetted perimeter of the conduit. Minor losses are caused by disruption to the flow due to bends, cross-sectional changes, fittings such as manholes and steps in the bed profile. Major losses are represented through the specification of a friction coefficient. The representation of minor losses, particularly or gravity networks, is at manholes and requires separate treatment. The default TUFLOW/Estry manhole loss approach uses the Engelund method explained in section 5.12.5.4 of the TUFLOW user manual. The Engelund approach provides an automatic method for determining the loss coefficients as presented below. Of note is that the coefficients are recalculated every timestep, and therefore vary depending on the flow distribution between inlet and outlet conduits and the depth of water within the manhole. The losses represented are as follows:

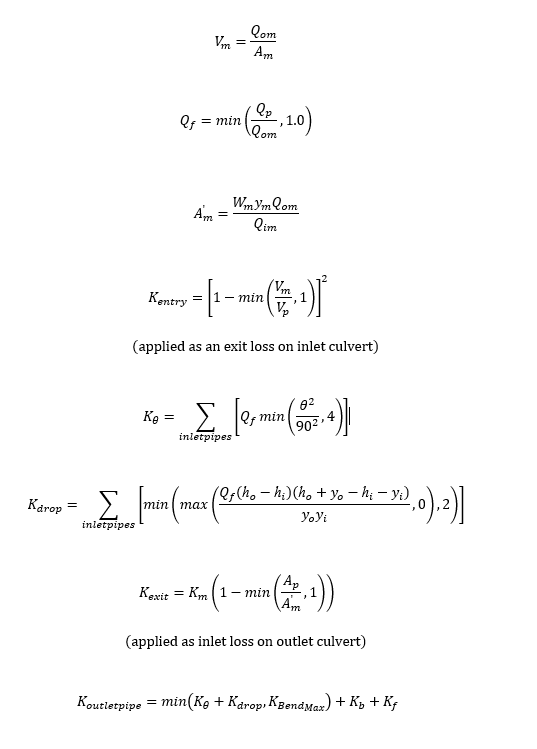

The equations used for the Engelund loss approach are provided below:

Where:

Qp = Flow in Conduit

Qim = Total flow into manhole

Qom = Total flow out of manhole

yi = Height of inlet conduit

yo = Height of outlet conduit

hi = Inlet conduit invert

ho = Outlet Conduit invert

θ = Angle in degrees of inlet conduit relative to outlet conduit(θ = 0° "when the culverts are in line," θ=90° when the outlet culvert is at right angles)

Qp = Flow in conduit outlet

Wm = Flow width in manhole (1d_mh width attribute)

ym = Depth of water in manhole

Am = Flow are in manhole

A'm = Effective flow are in manhole

Ap = Flow area of conduit

Km = Manhole Loss Parameter (1d_mh Km attribute)

Kb = Bend Loss Coefficient (1d_nwk Form_loss attribute)

Kf = Fixed Loss (1d_mh K_Fixed attribute)

KBendmax = Upper limit to sum of Kθ and Kdrop (1d_mh K_Bend_Max attribute)

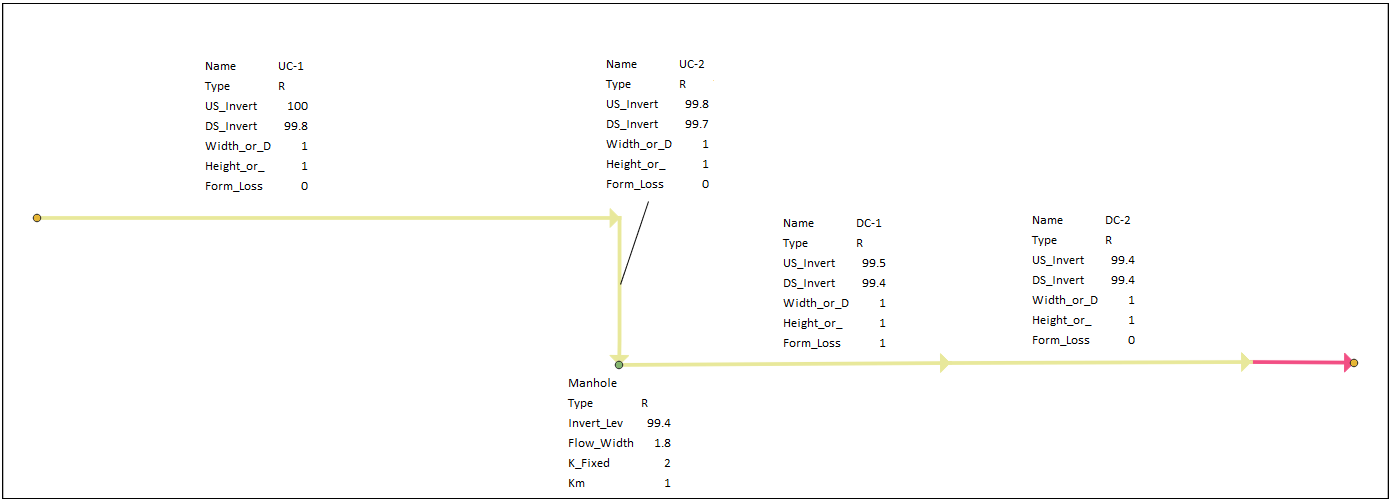

Below are three worked examples of the application of the Engelund method applied to a simple model for the following scenarios:

Single Incoming/Outgoing Pipe with No Incoming Angle or Drop

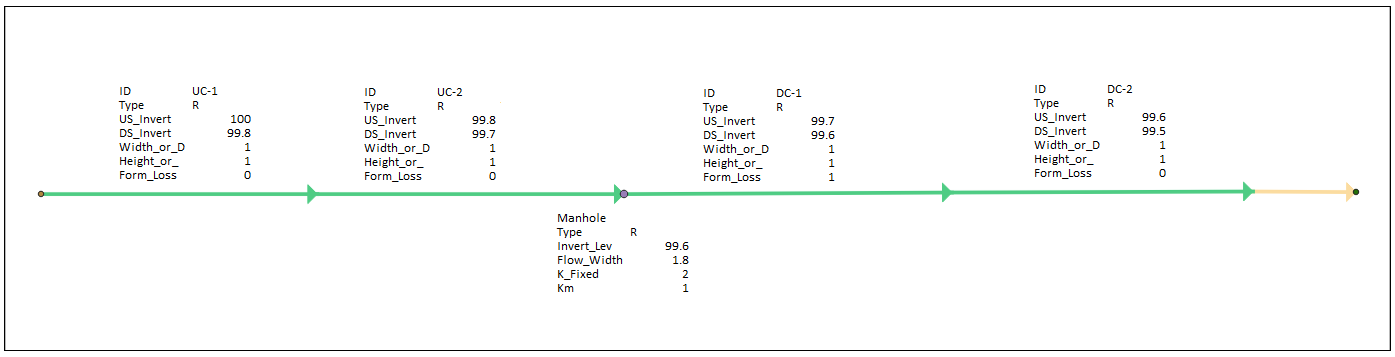

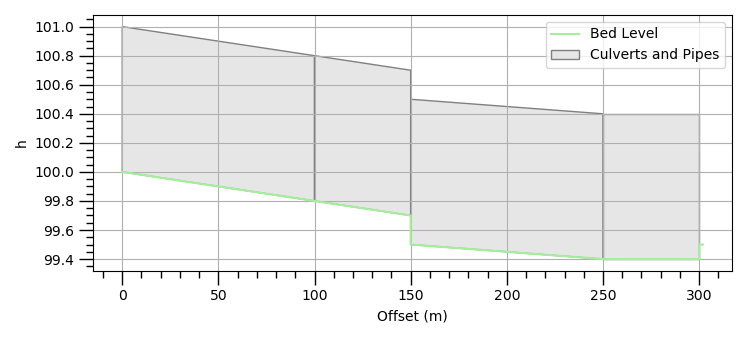

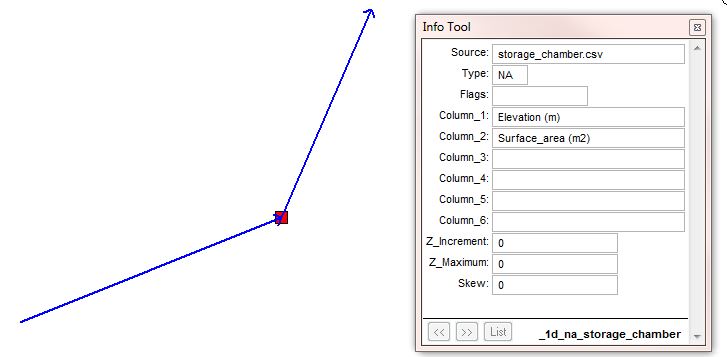

A simple TUFLOW/ESTRY model was set up as shown in Figure 1 with the parameters for the manhole and the links upstream/downstream of the manhole shown in Table 1.

Figure 1: Example Model 1 Network Schematic

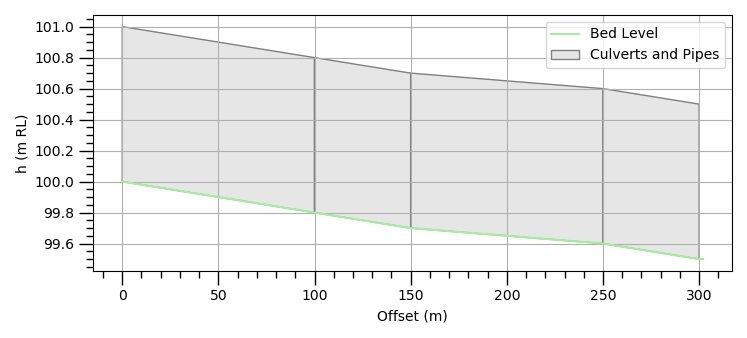

Figure 2: Example Model 1 Long Section

The model was run with a steady inflow of 2m3s-1.

The resulting losses from the 1 hour steady inflow simulation are presented in the following graph. Note that the following worked examples are based on output at Time=0.5 hours.

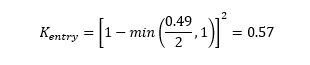

Example 1 - Entry Losses

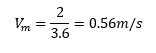

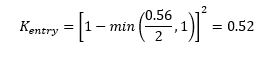

Entry losses are applied as an exit loss on the incoming conduit and are calculated as follows.

Where:

With other parameters defined in the section above.

The calculated flow area in the manhole is 3.6m2 and 1m2 in the adjacent culvert whilst the flow is 2m3/s for both Qp and Qom.

Therefore, Vm equals:

And Vp:

Using these in the Kentry equation provides a loss coefficient of:

The value matches the downstream loss coefficient for the upstream conduit shown in Figure X. The loss values are also shown in the *_TSL_P.shp file with the third value for the upstream conduit providing the entrance loss value.

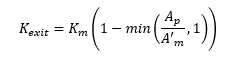

Example 1 - Exit Losses

Exit losses are applied to the upstream end of the outgoing conduit and are calculated as follows:

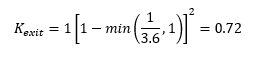

From table 1, we can see that Km is set to 1. Ap and A’m are 1m2 and 3.636m2 respectively. Therefore, Kexit is:

Figure X shows that the calculated value matches that provided in the TUFLOW results. The value is also reported as the first value for the downstream conduit in the *_TSL_P.shp layer.

Example 1 - Outgoing Conduit Losses

The loss coefficient for the outgoing pipe represents the losses due to the incoming angle of the upstream conduit, any drops in inverts levels between the incoming and outgoing conduits, bend losses and any additional form losses. It is calculated as follows:

The default value of KBend_max is set to 4 but can be changed via the 1d_mh K_Bend_Max attribute. As shown above we have no angle for the incoming pipe and no drop in invert levels. Table 1 shows the K_Fixed is equal to 2 and the outgoing pipe has a form loss coefficient, to represent bend losses of 1. Therefore Koutletpipe is:

This matches the value within Figure x and the middle value for the downstream conduit in the *_TSL_P.shp, representing the outlet conduit losses, of 3.

Single Incoming/Outgoing Conduit with Incoming Bend and Drop in Invert Levels

In this example, we will use the same simple setup but this time there is a 90 degree angle between the incoming and outgoing pipe as shown in the plan view in the figure below.

Figure 4: Example Model 2 Network Schematic

There is also a drop between the invert elevation of the incoming and outgoing conduits as shown in the difference in invert levels in table 2 below and the long profile in figure 5 . All other model parameters were kept the same including boundary inflows.

Figure 5: Example Model 2 Long Profile

The resulting simulated losses are shown in the below figure.

Example 2 - Entry Losses

In this example, the flow area in the manhole is 4.12m2 and 1m2 in the adjacent culvert whilst the flow is 2m3/s for both Qp and Qom.

Therefore, Vm equals:

And Vp:

From this:

Which matches the value in figure x.

Example 2 Exit Losses

Storage chambers

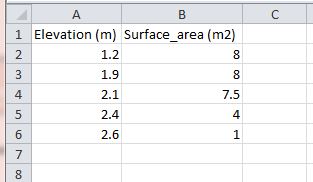

Storage, including storage chambers or floodplain storage, can be manually defined using a 1d_na (1d_tab_empty) node that has an assigned elevation versus surface area table. For the purpose of this page, manmade storage chambers have been discussed although the method is the same for all applications.

An example of a chamber:

Methodology

- Import 1d_na node.

- Assign the name of the elevation vs area csv.

- Specify the names for the elevation and surface area columns

storage_chamber.csv

For more information on storage nodes see Section 5.10.3 Storage Nodes (User Defined NA Tables) within the TUFLOW manual.

Any further questions please email TUFLOW support: support@tuflow.com

Back to 1D Hydraulic Structures