1D Pumps

Introduction

This post provides a modelling example for a 1D pump using a pump curve. For this example we will set up a pump in two common situations (2D-2D & 1D-2D).

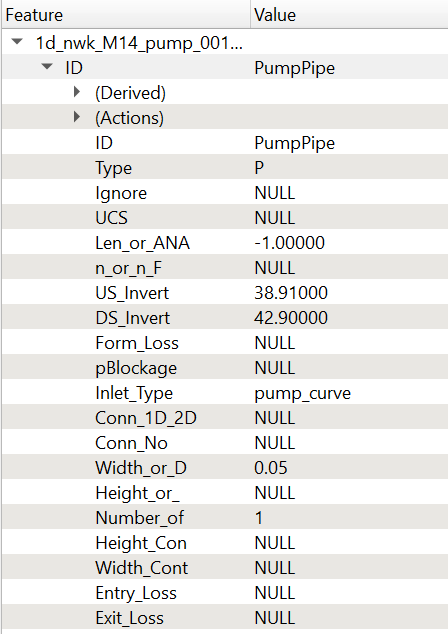

Pump Attributes

A pump needs to first be digitised in a 1d_nwke layer. The direction of the polyline must go from inlet to outlet as a pump is unidirectional (see Section 5.9.2.1 Pumps). The attributes required for a pump in your 1d_nwk layer can be found in the TUFLOW Manual.

In the 1d_nwk layer, the following attributes are required:

- ID = ID of the pump channel.

- Type = "P" or "PO".

- US_Invert = Intake elevation of the pump.

- DS_Invert = Outlet elevation of the receptor.

- Inlet_Type = Used to specify the pump curve in the Depth Discharge database.

- Width_or_D = Diameter of the pump’s outlet pipe/hose.

- Number_of = Number of (identical) pumps.

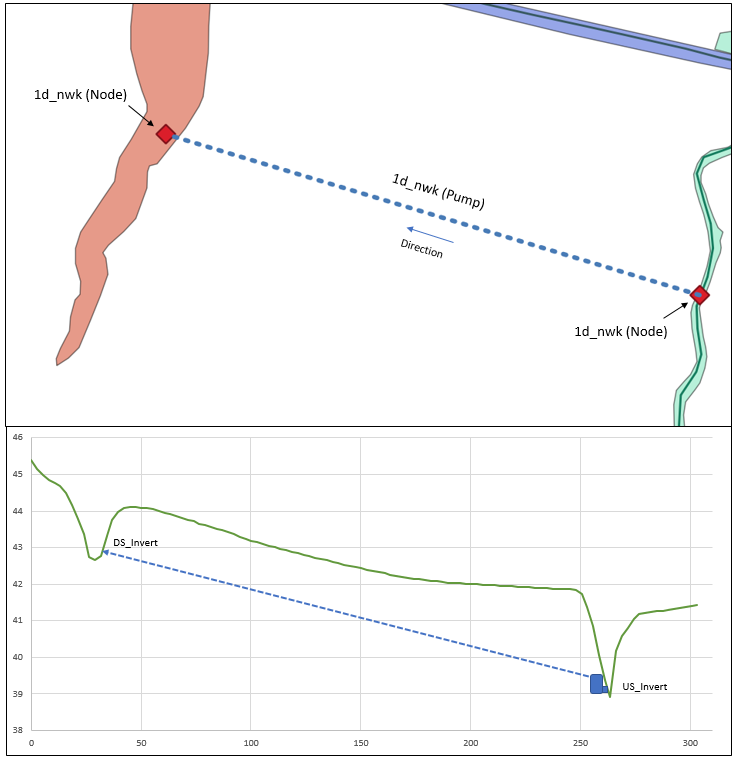

2D-2D Configuration

Because pumps are zero length channels they do not create automatic nodes at the upstream and downstream end. If you ran the model with just a pump polyline and SX connection you will get ERROR 1353 - No NA data for Node.To remove this error, the most efficient schematisation is to digitise a 1d_nwk 'NODE' at the upstream and downstream end of the pump (no need for a separate 2d_bc SX layer). The 'NODE' requires a nominal storage amount in the “Len_or_NA” attribute, in addition infill 'SX' into the "Conn_1D_2D" attribute to connect the 1d pump to the 2D domain. SX connections are required at connections to 2D domains to transfer water from the 1D node to the 2D. Without the SX connection, water will build up within the node and cause an instability. See the example below.

A simple 2D-2D pump configuration will look like the below schematisation.

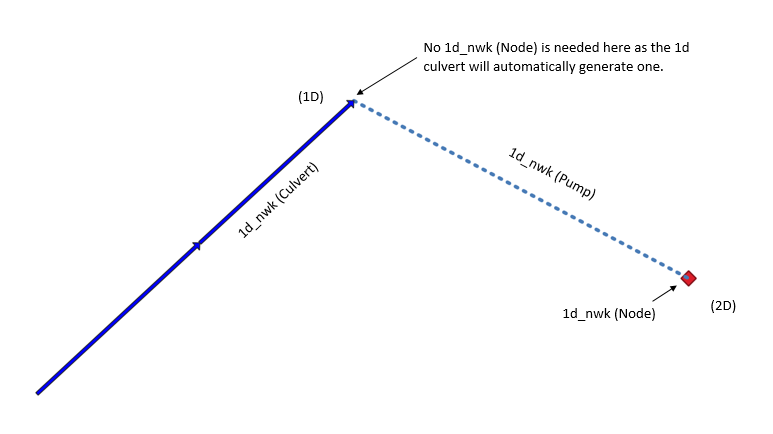

1D-2D Configuration

Connecting a pump from a 1d network to the 2d domain or vice versa is similar to the configuration above, the only difference is that the connection with a 1d structure does not require a 1d nwk ‘Node’. A storage chamber in the 1d network can also be modelled using a 1d_na node with an elevation vs area .csv assigned to the node.

Estry Control File Setup

Within the *.ecf the following commands and files are required to run a pump with no logical controls:

Read GIS Network ==..\model\mi\1d_nwke_xxxxx.MIF

Depth Discharge Database ==..\bc_dbase\xxxxx.csv

If you do not specify a Depth-Discharge database then you will be faced with ERROR 1118 – Could not find a y-Q curve.

TUFLOW Operating Control File (.TOC)

For guidance on setting up the operating controls for pumps, refer to the TUFLOW Manual.

.ecf command required:

Read Operating Controls File == xxxxx.toc

Depth Discharge Database

The depth discharge database is set up in the same way as a pit inlet database (refer to the TUFLOW Manual). Each pump ‘Inlet_type’ must reference a name within the depth discharge database, otherwise ERROR 1118 - Could not find pit inlet type ",a," in the pit inlet database. The ‘Area (m2)’ column is the area of the pump offtake and ‘Width (m)’ column is the width of the pump offtake. Without information in the Area(m2) or Width(m) columns in the depth discharge database Error 1092 and Error 1093 will appear.

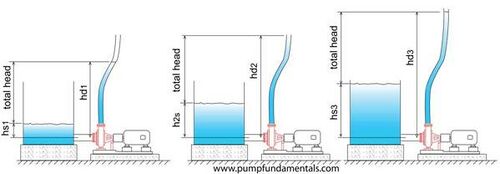

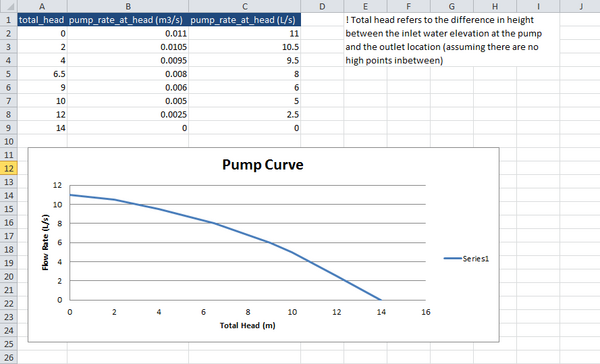

Pump Curve

The performance of pumps is a function of suction head at the inlet and the level of the discharge location. The resultant total head between the water level at the inlet and outlet is what determines the flow rate through the pump. If the suction level is low the pump will need to provide more energy in the form of pressure to maintain the water elevation at the outlet, the opposite is also true if the water depth at the pump inlet is high.

That being the case it is important to consider what total head is required to achieve the modelling objectives and what flow rates you may require. Once you have an idea on any limits in total head you can start to research an appropriate pump and then extract the performance curve that is often incorporated as part of the technical specifications. An example is shown below.

Creating a TUFLOW pump curve

The setup of the Depth Discharge database for a pump curve is similar to reading in inflow hydrographs, hyetographs etc, that is; a source .csv, and the two corresponding headings within the 3rd and 4th column.

Once you have your manufacturer curve for your given pump it is now necessary to create the curve .csv for TUFLOW to read in. The manufacturer specifications will need to be translated into a total head vs pump rate chart. Although reading in the depth discharge database is the same process as other boundary conditions within TUFLOW, the curve itself is fundamentally different as you no longer need to start the csv file with 0,0. If the curve did start at 0,0 this would not make sense because at a total head difference of 0m the pump should effectively be operating at peak performance so the flow rate would be greater than 0 m3. The image below shows a csv file for the pump performance curve given in the previous section.

Using a Pump Curve in a TUFLOW Operating Control (TOC) File

With the pump curve defined in the depth-discharge database it can either be specified within the pump 1d_nwk fields in the inlet_type field, for non-operational pumps, or it can be defined with the TOC file, for operational pumps. When defining with a TOC file, the pump curve is defined at the top of the structure control definition block and then the subsequent rules can turn the pump on/off. See the below TOC structure control definition for an example. In this case, the pump curve is used when the pump switches on once upstream water levels reach 2.75m AD. The pump curve is then used until the upstream water levels are reduced to 2.25m AD at which point the pump is switched off.

Define Pump Control == Pump_1

Pump Capacity == pump_1

HU == H1D Pump1.1

If HU <= 2.25

Pump Operation == Off

Else if HU > 2.25 AND HU < 2.75

Pump operation == No Change

Else if HU >= 2.75

Pump Operation == On

End if

End define

1D Result File

Although strictly not a check file, the operation of the pump can be confirmed by opening the *_1d_O.csv which is found within the csv folder where the results are written. The *_1d_O.csv monitors the operation of structures, this file can be quite useful in checking how the structure is performing with the given .toc file and GIS inputs.

| Filename prefix / suffix | Brief Description |

|---|---|

| _1d_O.csv | This csv displays the status of the pump, whether that is closed or fully open, results for any logic parameter specified in the TOC file and the flow through the pump if it is in operation. |

Any further questions please email TUFLOW support: support@tuflow.com

| Up |

|---|